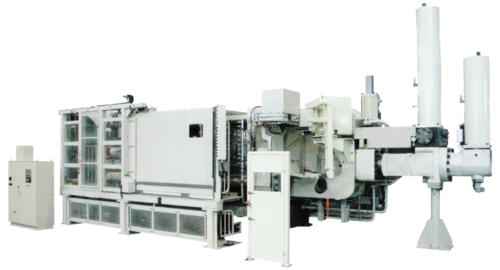

Servo injection die casting machine DC R-M/R-H

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow-speed propulsion and multi-stage slow-lifting, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, the acceleration performance can reach 70G, which can realize filling in a short time.

1. It adopts the exclusive high-flow hydraulic multi-stage servo technology, which is responsive and can do complex and fast acceleration and deceleration movements.

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow propulsion and multi-stage slow rise, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, the acceleration performance can reach 70G, which can realize filling in a short time.

4. Deceleration section: the oil outlet side is closed instantaneously to achieve rapid deceleration.

5. Unique injection closed loop real-time feedback + learning control function, when the actual injection curve is deviated from the setting, it can also be corrected back to the set injection curve, especially the high-speed filling section can achieve long distances that other cards cannot achieve The continuous speed plateau area makes the high-speed filling section that occurs at the same time as solidification, and the speed is constant and stable.

6. Boosting section: Divide the injection part and boosting part oil circuit to achieve a short-term boost.

7. With the latest compound pressurization start control method of pressurization, it can overcome the unstable pressurization start timing caused by fluctuating factors of soup volume, and ensure that the actual pressure of the casting is stable.

8. Optional dPAQET, real-time monitoring software, to achieve the concept of industry 4.0 production data mastery.

9. Optional mechanical center point injection function, which provides a better choice for the casting of round castings.

10. Optional ultra-high-speed and large-flow servo valve, that is, RH model, the acceleration performance is increased to 100G, especially for difficult-to-cast die-casting parts with complex shapes, or magnesium alloy die-casting parts with faster solidification speed, to further improve the acceleration performance A grade to meet more stringent quality requirements. If it is used on aluminum alloy die castings, the higher the rate of fire also means that when casting a larger area of the mold, the better the filling efficiency of the end, the customer will be able to challenge a larger area with the same tonnage machine Mold in order to create a differentiated competitive advantage with different quality from other die-casting plants.

1. Different from traditional die-casting machine, there are only three-stage control of high speed, low speed and boost pressure.

2. The world's leading servo multi-segment injection function:

(1) Low-speed section: the lowest speed can be slowed down by 0.03m/s, and multi-stage slow rise can be set to greatly reduce the chance of entrainment.

(2) High-speed section: Through the large flow control on the oil outlet side, the filling can be realized in a short time. Before the metal solution solidifies, pressure is applied to further reduce the pores.

(3) Deceleration section: Through the instantaneous closing of the oil outlet side, rapid deceleration is achieved, and problems such as product flash and mold erosion are reduced.

3. Pressurization section: Split the injection part and the pressurization part into two oil circuits, which can shorten the pressure rise time, improve the pressure transmission, and compress more effectively to reduce the pores.

4.

(1) In the past, most die castings used a fixed point before the end of the runaway stroke as the position where the booster was opened. However, when the soup cake is too thick, the pressurization position may not be reached, or the pressurization start is too slow, resulting in no substantial effect of the pressurization, the pores cannot be effectively compressed, and the quality of the pores is too large.

(2) When the soup cake is too thin, the boost pressure will be exerted prematurely, and the boost and the high-speed impact will merge. If the filling force is too large, the mold will be easily opened, causing flashing and loss of pressure in the casting. As a result, the pressurization has no real effect, and the air holes cannot be effectively compressed.

(3) Brand new "supercharged" start method

Use the injection stage to detect "injection speed" or "injection cylinder back pressure" to sense whether the aluminum material has been filled, you can determine the best time to turn on the pressurization, for example, if you use injection Speed detection,

When the soup cake is too thick, the injection waveform is detected and the speed drops earlier, and the booster will be turned on earlier.

When the soup cake is thinner, the wave is detected and the speed drops slowly, and the booster will be turned on later.