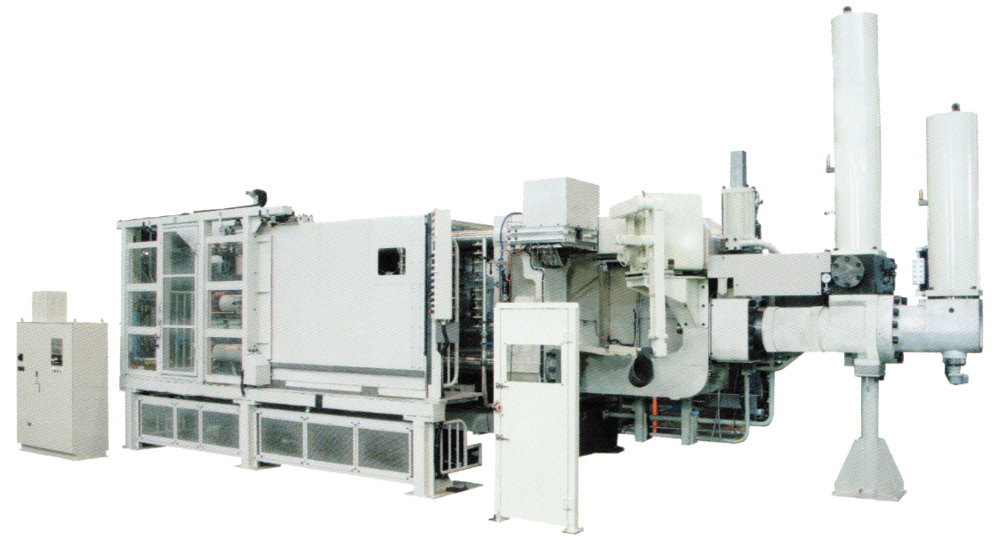

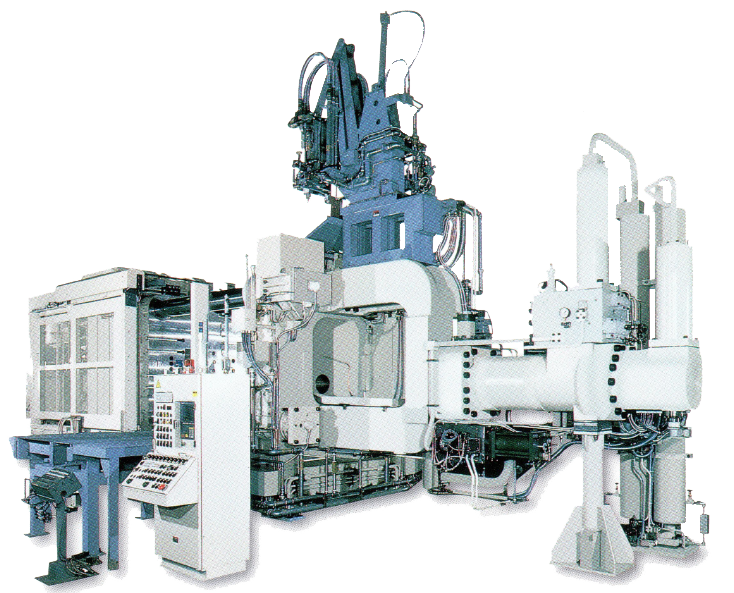

Large die-casting machine DC J-MC / CS series (1250 tons-3500 tons)

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow propulsion and multi-stage slow rise, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, filling can be realized in a short time.

1. It adopts the exclusive high-flow hydraulic multi-stage servo technology, which is responsive and can do complex and fast acceleration and deceleration actions.

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow propulsion and multi-stage slow rise, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, filling can be realized in a short time.

4. Deceleration section: the oil outlet side is closed instantaneously to achieve rapid deceleration.

5. Unique injection closed loop real-time feedback + learning control function, when the actual injection curve is deviated from the setting, it can also be corrected back to the set injection curve, especially the high-speed filling section can achieve long distances that other cards cannot achieve The continuous speed plateau area makes the high-speed filling section that occurs at the same time as solidification, and the speed is constant and stable.

6.2250 tons or more is equipped with a pressurized clamping cylinder as standard, which can shorten the cycle time by about 1 second and improve production efficiency.

7. The elbow part adopts a fully quenched sleeve method to improve the rigidity of the machine and extend the life of the elbow.

8. J-MC series: Standard TOSLITE controller, simple setting mode, simple operation and can show the superiority of servo multi-segment injection. J-MC series can also be upgraded to TOSCAST controller.

9.CS series: standard TOSCAST controller, its powerful functions can meet the increasingly important needs of various detailed management.