Shibaura Mechanical Cold Chamber Die Casting Machine

Servo injection die casting machine DC R-M/R-H

1. It adopts the exclusive high-flow hydraulic multi-stage servo technology, which is responsive and can do complex and fast acceleration and deceleration movements.

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow-speed propulsion and multi-stage slow-lifting, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, the acceleration performance can reach 70G, which can realize filling in a short time.

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow-speed propulsion and multi-stage slow-lifting, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, the acceleration performance can reach 70G, which can realize filling in a short time.

Electric mold clamping servo injection die casting machine DC R-EM/R-EH/R-E

On the basis of the same functions of R-M/R-H, the unique electric motor drive and control technology elements of Shibaura Machine Group's machine tools and injection machines are used to take advantage of the multiple advantages of fast cycle, energy saving, clean environment and space saving.

1. Fast cycle:

(1) Compared with the hydraulic operation, the electric opening and closing of the mold itself is agile and fast.

(2) The electric mold opening and closing does not use oil pressure. Other actions in the cycle, especially the injection action after the mold closing, can complete the pressure compensation faster, and the injection is earlier, which speeds up the cycle time.

(3) The electric mold opening and closing action can perform the advance action of the soup during mold closing and the advance action of the take-out machine during mold opening to strive for the possibility of accelerating the cycle time.

1. Fast cycle:

(1) Compared with the hydraulic operation, the electric opening and closing of the mold itself is agile and fast.

(2) The electric mold opening and closing does not use oil pressure. Other actions in the cycle, especially the injection action after the mold closing, can complete the pressure compensation faster, and the injection is earlier, which speeds up the cycle time.

(3) The electric mold opening and closing action can perform the advance action of the soup during mold closing and the advance action of the take-out machine during mold opening to strive for the possibility of accelerating the cycle time.

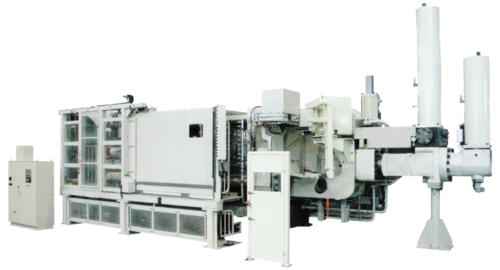

Large die-casting machine DC J-MC / CS series (1250 tons-3500 tons)

1. It adopts the exclusive high-flow hydraulic multi-stage servo technology, which is responsive and can do complex and fast acceleration and deceleration actions.

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow propulsion and multi-stage slow rise, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, filling can be realized in a short time.

2. The low-speed section can reach as low as 0.03m/sec, which can be used for slow propulsion and multi-stage slow rise, which can greatly reduce the chance of entrainment.

3. High-speed section: Through the large flow control on the oil outlet side, filling can be realized in a short time.

Small die-casting machine DC 135J-SC /J-T2 series

1. The speed capability is increased by 33% compared with the previous one, and the injection force is increased by 19% compared with the previous one. Although the tonnage is small, high-quality casting process can be realized.

2. The same clamping part design is adopted as the 250 tons and 350 tons. The ejection hydraulic cylinder is independent and has no guide pillars. The rigidity is improved and the convenience of the ejection pin installation and removal operation and cleaning can be realized.

3. J-SC adopts CASTEYE controller, simple and convenient man-machine operation interface, which improves the convenience of on-site operation.

2. The same clamping part design is adopted as the 250 tons and 350 tons. The ejection hydraulic cylinder is independent and has no guide pillars. The rigidity is improved and the convenience of the ejection pin installation and removal operation and cleaning can be realized.

3. J-SC adopts CASTEYE controller, simple and convenient man-machine operation interface, which improves the convenience of on-site operation.